Marine Applications

We have vast experience delivering the right variable frequency drives into Marine applications.

Saving energy, Cutting CO2 emissions

Energy efficiency is the single most important factor in reducing CO2 emissions. OPTIDRIVE™ variable speed drives from Invertek Drives can cut the energy consumption of fans, pumps and compressors found on marine vessels by as much as 60%.

OPTIDRIVE™ delivers reliability, high performance and efficiency in a compact, easy to use unit made for marine environments.

Integrated safety

OPTIDRIVE™ VFDs provide SIL2 (Safety Integrated Level) functional safety standards based on the IEC 61508, providing complete peace of mind.

OPTIDRIVE™ is approved by DNV, an independent globally renowned foundation with the objective of safeguarding life, property, and the environment.

Onboard Applications

We have vast experience delivering the right variable frequency drives into marine onboard applications applications.

-

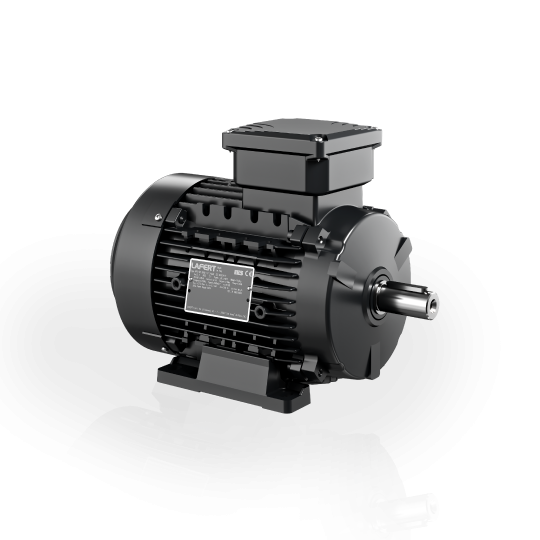

Cranes

OPTIDRIVE™ variable speed drives have been successfully operating in a wide range of crane and hoist applications throughout the world for many years. Optidrive provides an excellent solution, allowing operation across a wide speed range whilst maintaining full load capability. This allows low speed movement for delicate operations requiring careful positioning and control to be achieved, whilst also allowing high speed movement to ensure operating time is minimised where practical. Optidrive P2 provides proven high performance motor control, particularly suited to the demands of crane and hoist applications. Up to 200% of torque is available from zero speed, even in open loop applications without encoders fitted. Dedicated “Hoist Mode” operation ensures the motor brake is correctly and safely controlled, and maintains safe operating conditions at all times. In addition, this minimises wear on the hoist brake, and reduces mechanical shock loads, prolonging service life and reducing maintenance costs.

-

Winches

OPTIDRIVE™ P2 provides direct control of both motor torque and speed, with extremely fast dynamic performance necessary to meet the demands of winch applications, whether operating with encoder or open loop without encoder. Torque and speed may be simultaneously controlled, allowing the drive to be adapted to many different winch applications, such as mooring, anchoring or working winches. Overload capacity of 200% for up to four seconds as standard ensures that high peak torques are possible where required. The extremely high level of performance and dynamic control ensures Optidrive P2 is suitable for auto tensioning applications — maintaining the correct level of winch tension in all operating conditions.

-

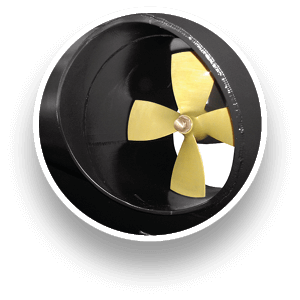

Bow Thrusters

Using OPTIDRIVE™ to regulate thrusters provides the level of dynamic control necessary for precise operation, maximising manoeuvrability of vessels. Pitch control may be eliminated, whilst operating noise is also reduced. Overall energy efficiency is also improved, thanks to the rapid control response, with further benefits of improved reliability and reduced maintenance.

-

Ventilation

Variable speed control of fans has long been proven as the most efficient method for controlling airflow volumes to directly match requirements, thereby reducing energy consumption and saving money. OPTIDRIVE™ HVAC and HVAC Eco drives are designed to offer the maximum possible levels of efficiency in fan control applications, whilst providing a wealth of additional features to ensure simple installation and easy set up. A dedicated Fire Mode operation ensures ventilation is maintained in emergency conditions. Resonance avoidance also ensures that the fan never operates at a speed which may create unwanted audible noise, providing quiet, efficient operation through the required speed range.

-

Pumps

OPTIDRIVE™ HVAC and HVAC Eco feature Invertek’s unique Optiflow technology, providing reliable and efficient operation in a wide range of pumping applications. The internal PID controller allows the drive to automatically maintain a present pressure or flow level. Multiple drives may be networked together for typical Duty / Standby or Duty / Assist configurations, minimising the installation and commissioning time, and removing the need for external controllers. Operation with the latest high efficiency PM and Synchronous Reluctance motors is also possible, ensuring the most energy efficient solution is achieved.

-

Compressors

Applying OPTIDRIVE™ variable speed drives to air and refrigeration compressors allows the compressor speed to be automatically adjusted to accurately match the requirements, providing flexible, energy efficient control under all operating circumstances. Compressor speed is maintained within the correct range at all times to ensure reliability is maintained.

Sumitomo Drive Technologies - products for Marine