Pump control

We are experienced with thousands of diverse pump control applications around the World.

Pumping systems account for nearly 20% of the worlds electrical energy demand. Oversized pumps, lack of speed control and energy management can waste huge amounts of energy. Variable Frequency drives offer significant and immediate savings for all pumping applications.

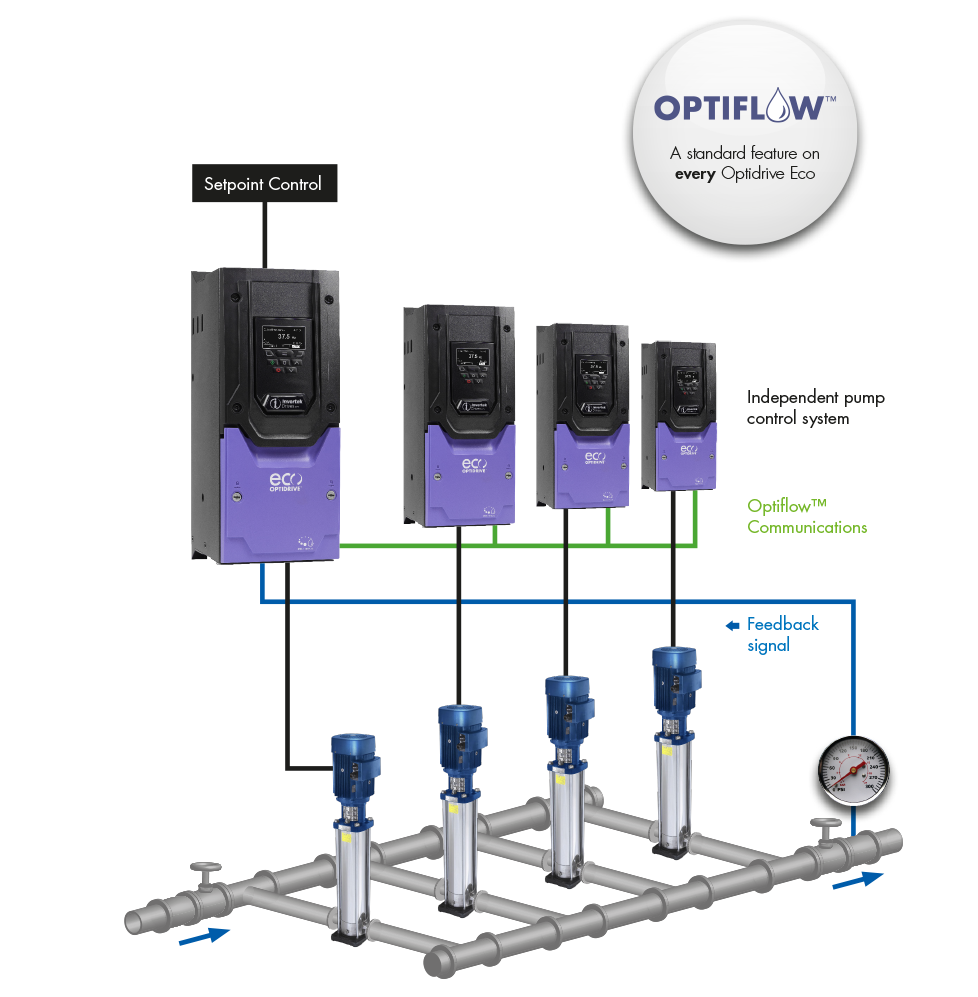

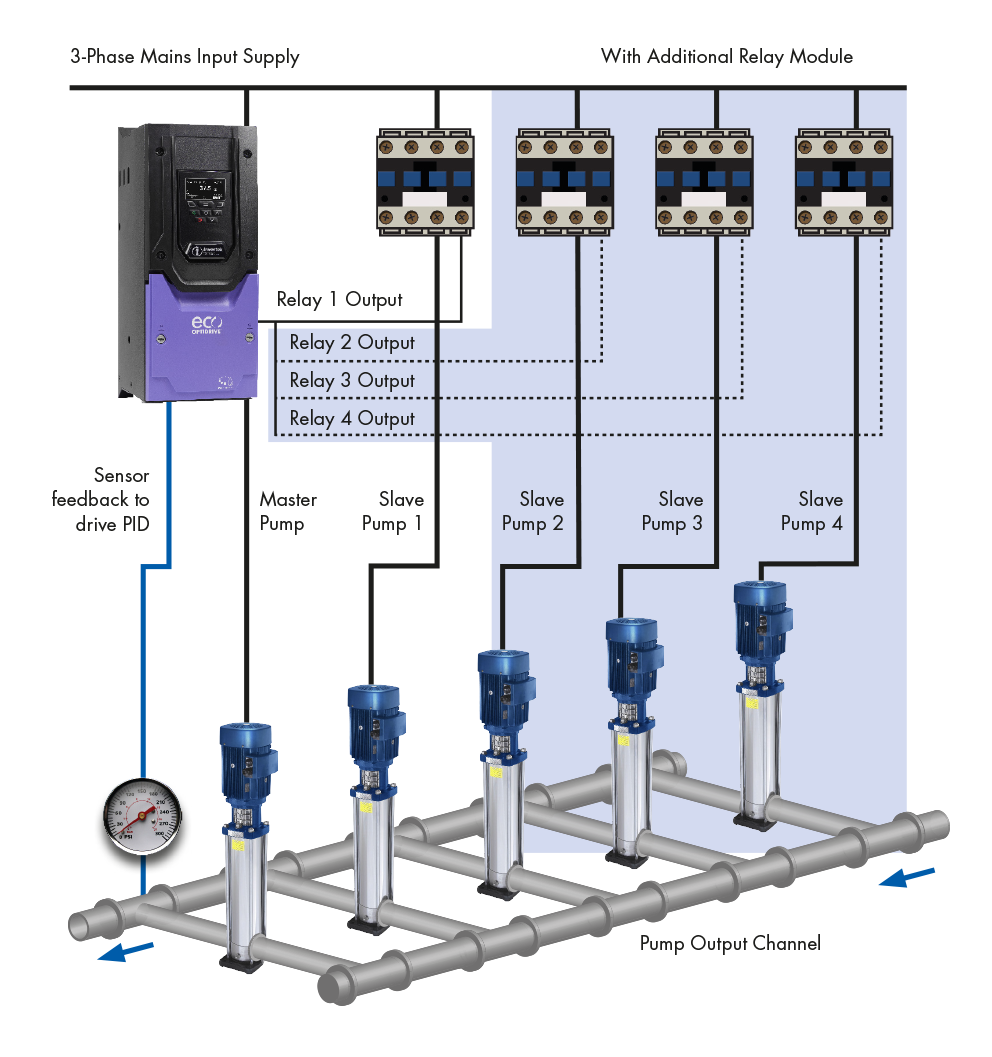

Standalone flexible pump station control using VFDs

A single master VFD controls and monitors the system, as up to 5 pumps can operate in duty, assist or standby modes. Required pressure and flow levels are maintained as demand for water varies. If one pump requires maintenance the remaining pumps provide a seamless service. Configurable cleaning cycles can be run to clear sediment from the pump and Optidrive can act as a bypass controller when installed as part of a bypass circuit, ensuring pumping is maintained even if a trip condition in the drive is encountered.

Blockage detection and clear

Optidrive VFDs can detect pump blockages and run a programme to clear them. They can protect pumps by shutting off when the pump runs dry and pre heat motors to remove any condensation prior to motor start up.

Pump prime and leak detection

Pump prime mode in the Optidrive helps prevent the effects of water hammer and potential damage to sprinkler or fountain heads. Having a set time for the system to pressurise allows the VFD to detect a leak in the system and immediately shut down the pump.

Pump Pressure control with DOL (Direct Online) pump assist.

A cost effective and simple, solution for standard boosters capable of managing multiple pumps using one drive

Process Control and Automation

In many cases, the speed of a motor can directly influence the result of a process. For example, the speed of a mixer in a treatment tank can affect how well the wastewater is treated. By using a VFD, the speed can be finely controlled, which can improve the effectiveness of the process.

Pressure Regulation in Water Supply Systems

In water supply systems, pressure often needs to be kept within a certain range. If the pressure is too high, it can cause pipe damage and leaks. If it's too low, it can lead to inadequate water supply. VFDs can help maintain the correct pressure by adjusting the speed of the pumps.

Aeration Control in Wastewater Treatment

Aeration is a crucial process in wastewater treatment. It's used to encourage the growth of aerobic bacteria, which consume organic matter in the wastewater. The amount of air required can vary depending on the amount of organic matter present. VFDs can be used to adjust the speed of the blowers that provide the aeration, maintaining the correct oxygen levels in the wastewater.

Sludge Dewatering

In sludge dewatering processes, VFDs can regulate the rotation speed of the decanter centrifuge, controlling the solid-liquid separation process, enhancing the dryness of the sludge, and reducing the volume for disposal.

Reducing Mechanical Stress

Starting a motor can cause a significant mechanical stress. By using a VFD, the motor speed can be ramped up slowly, which can reduce the mechanical stress and extend the life of the equipment.

Sumitomo Drive Technologies - products for Water & Wastewater