Energy Saving with Variable Frequency Drives

Article 8

In the last article we looked at using the parameter settings to match the drive to our control methods and needs. Now let’s look at a wider topic; energy saving.

There are many reasons for using variable frequency drives. They make process control and machine operation much easier; they reduce inrush current and make starting more controlled; they reduce unnecessary noise and wear. But one of the key advantages is that they will often reduce your power bill.

Before we go into the savings from the drive, we should remember that motor efficiency is also important. European legislation now basically says you can’t buy an IE1 motor (the least efficient); if you buy an IE2 motor you must use it with a variable frequency drive.

Now the cost of the motor is only one or two percent of the total cost of ownership due to the energy it consumes in its lifetime, so in addition to the legislation, it makes sense to look at IE3 and IE4 motors, which are now widely available. More exotic motors, such as permanent magnet motors, will offer even greater efficiencies when used with a drive, but more on that in a later article. And while you’re selecting the motor, remember that most motors are more efficient when they are running close to their rated power, so don’t pick a bigger motor than is needed.

Back to variable frequency drives. If you reduce the speed of a motor using a drive you will almost certainly reduce the power you consume. If the load is a constant torque load, the power will be proportional to the speed. A constant torque load is one where the load doesn’t change too much with speed; conveyers, mixers, many small machines. However, in these applications process control is often more important than energy saving.

Incidentally, running the drive in Vector Control will often result in a reduction in energy consumption because the drive is continually adjusting the voltage and frequency to optimise the motor operation. This is particularly useful with constant torque loads as it gives the best performance as well. Invertek E3 now operates in Vector Control as standard, and the P2 range is easy to set up in Vector mode. Try it and check out the reduction in motor current by looking in the display.

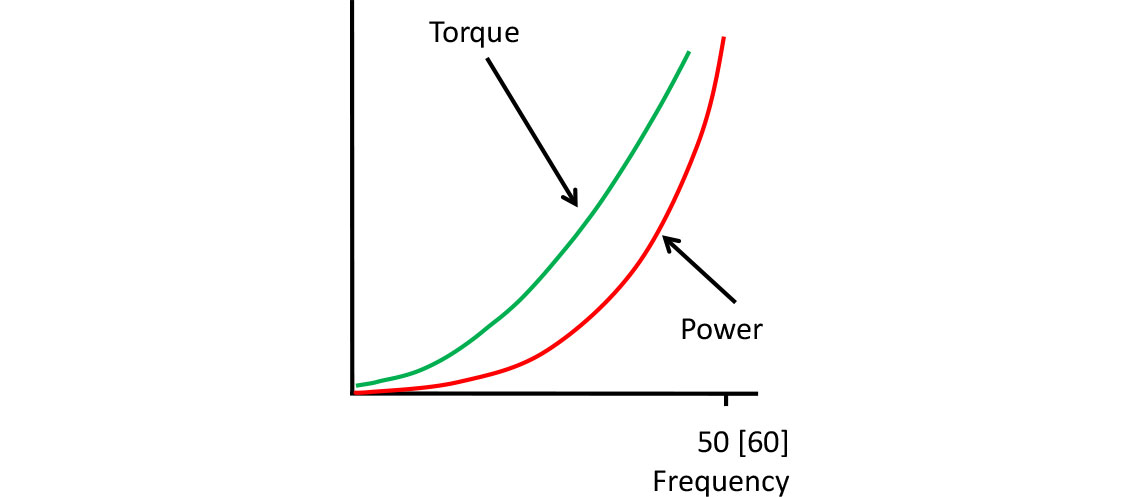

However, variable frequency drives really start paying for themselves with variable torque loads; that is, loads that increase with speed. Most fans and many types of pumps are variable torque loads – in fact, the torque increases with the square of the speed. This means the power is proportional to the cube of the speed (see Figure 1).

So reducing the speed of a pump or fan by 10% reduces the power consumption by about 25%, even allowing for the losses of the drive (typically about 3%). Reduce the speed by 20% and you’ll be getting close to halving the energy consumption. Note that some pumps, such as positive displacement pumps, are constant torque loads and work better with an industrial, or constant torque setting using an E3 or P2 drive.

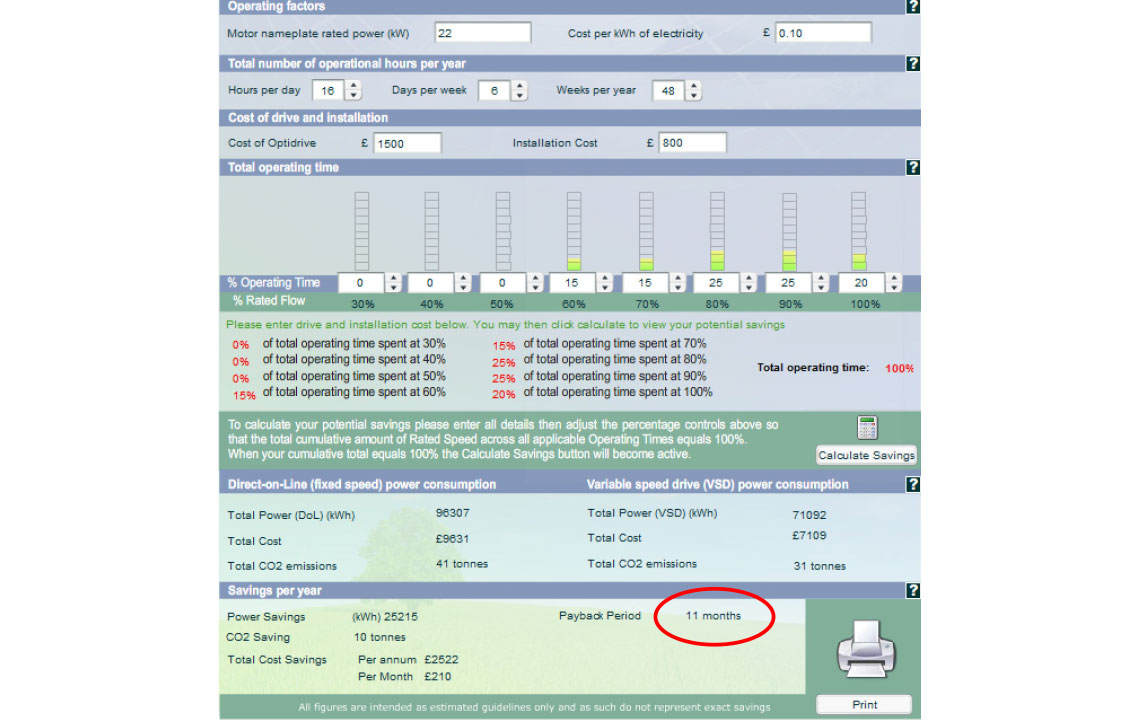

Now of course if you fit a variable frequency drive and just run the pump or fan at full speed you’ll get no saving, but if you reduce the speed – even a little - the payback time will probably be months, not years. Drive suppliers will offer you a nice calculation sheet to show these savings; if a particular drive shows better results than others, be suspicious – it’s the physics of the pump or fan that gives the saving, and should be pretty much the same for all drives. Figure 2 shows a typical calculation sheet; the drive runs mostly at 70 – 90% of full speed and the payback time is eleven months. You can download this calculator from here

If you want to get the best from the drive, don’t just turn the speed down a little and hope the process won’t be affected. You could fit a sensor, connect that back to the drive and use the closed loop control in the drive to maintain the flow rate, temperature or pressure or whatever automatically. We’ll look in detail how to do this in a later article. You can now remove those clumsy throttle valves and dampers and watch the energy savings mount up.

Or you could simply use a timer and drive on that fan that runs all the time, selecting a slower speed at night and weekends.

Because fitting a variable frequency drive to a pump or fan is so cost effective and easy, it isn’t surprising that about half the applications for variable frequency drives involve these variable torque loads. Remember as well as saving energy and improving control, starting currents are reduced and shock and vibration largely eliminated. Better all round in fact.

Most drives manufacturers will offer a special range of drives optimised for pump and fan applications. These drives don’t have the sophisticated control and overload features of an industrial (i.e. constant torque) drive, but they often have additional features useful for pumps and fans. For example, the Invertek Eco drive has special software to control several pumps when operating in cascade mode; it has a pump cleaning function that detects blockages and clears them; it will save energy by entering standby mode when there is no demand etc. Some Eco drive variants could also save money because of their low input harmonics; inductors aren’t needed and the effective input current reduced.

So the drive saves you money and brings additional control features; what’s not to like?

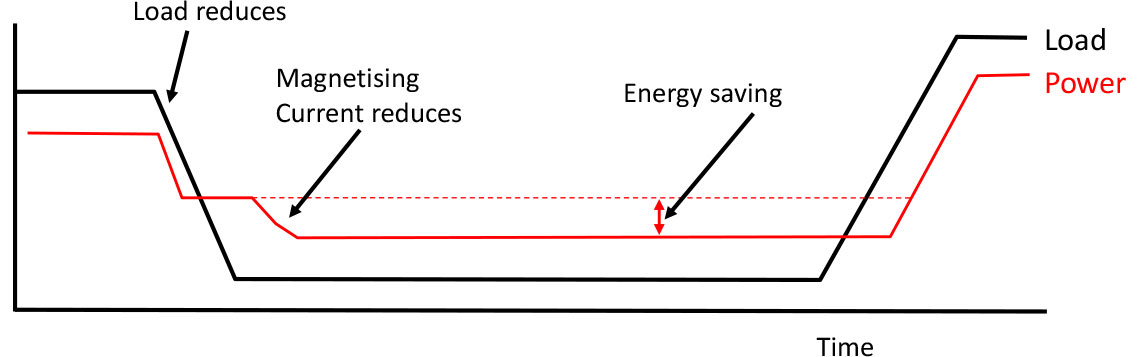

Finally, let’s not forget the simple ‘Energy Saving’ function that is standard on all Invertek drives. This feature continually monitors the load on the drive, and if the load is light, it reduces the magnetising current (effectively by reducing the output voltage slightly) in the motor, which reduces losses in the motor and drive. The downside of this is a small delay in taking up a sudden load; in many applications you wouldn’t notice it. The saving is not great, sometimes reported as one or two percent, but every little helps doesn’t it? Parameter P-06 in E3 (P1-06 in P2 and Eco) enables this function. Figure 3 shows the function in action.

It’s worth emphasising again the massive savings you can make when you fit a drive to a pump or fan; Variable frequency drives have now largely replaced other methods of flow and pressure control in air handling systems, but there are still many energy saving opportunities waiting for a drive.

In the next article we’ll look at closed loop control using a variable frequency drive.