Creating comfortable building environments without high energy costs

Where do the energy savings come from?

Air conditioning can use a huge amount of energy. In some cases it could even double energy consumption, not to mention the resultant increase in a company’s carbon footprint.

Don’t produce more airflow than you need!

Typically the air conditioning systems in buildings are designed for maximum occupancy and peak outside ambient. This means that for the majority of time there is large scope for running the systems at reduced speed and significant money to be saved with variable speed drives. Optidrive Eco can vary the output of your air conditioning system to meet the varying demands throughout the day.

Stairwell (escape route) pressurisation systems are being extensively employed in large buildings and complexes to help ensure the safe evacuation of occupants during a fire. Variable speed drives are playing an increasing role in maintaining pressures (of approximately 50 Pa) within these critical areas. Here Optidrive Eco is used to provide a smoke free escape by accurately maintaining the air pressure along that route.

Pressures must be maintained at a high enough level that a door opened between the fire floor and the escape route does not result in smoke entering the escape route. Equally, as doors and vents are opened along the escape route allowing air to escape the Optidrive and stairwell pressurisation system must increase output so that the required pressure is accurately maintained.

Many buildings now incorporate dedicated smoke management and extraction systems designed to safety exact smoke in the event of a fire, these systems are designed to localise and extract smoke such that the rest of the building remains smoke free and can be evacuated safely. Here the Optidrive’s Fire Mode function is critical in maintaining continued operation of the smoke extraction system for the longest permissible period.

For applications such as underground car parks the fans providing fresh air intake are often reversed in the event of a fire to provide smoke extraction. Optidrive Eco is easily configured for bi-directional fire mode operation.

Many buildings now incorporate dedicated smoke management and extraction systems designed to safety exact smoke in the event of a fire, these systems are designed to localise and extract smoke such that the rest of the building remains smoke free and can be evacuated safely. Here the Optidrive’s Fire Mode function is critical in maintaining continued operation of the smoke extraction system for the longest permissible period.

For applications such as underground car parks the fans providing fresh air intake are often reversed in the event of a fire to provide smoke extraction. Optidrive Eco is easily configured for bi-directional fire mode operation.

Optidrive Eco provides the ideal pump control solution for chiller, circulation and cooling pumps.

Dual Setpoint Control maximises energy savings by allowing pumps to be switched back to lower setpoints during quieter, low demand periods whilst maintaining full operation when required.

Advanced Optiflow Multi-pump Management allows pumps which operate in typical configurations such as Duty / Standby or Duty / Assist / Standby to be simply connected together using RJ45 patch cables and commissioned as a single pump set, saving installation and commissioning time and providing fully automatic duty changeover operation.

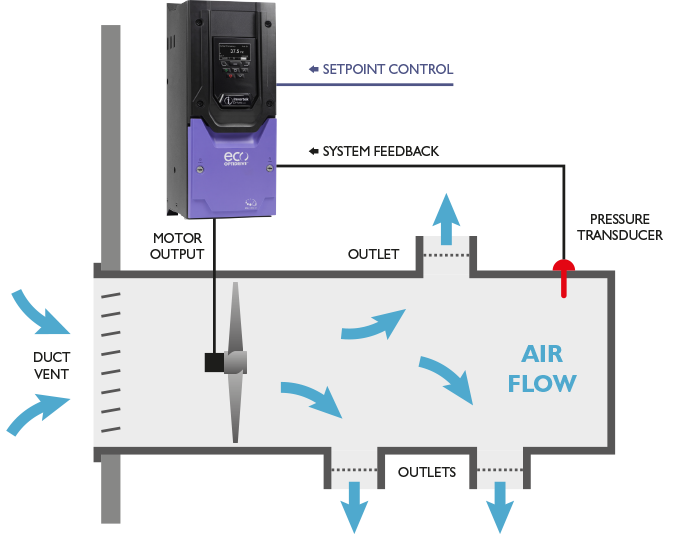

Controlling your HVAC System

Optidrive Eco has a PID controller built in that is fully integrated with both HVAC and energy efficient features and is packaged in a user friendly way to ensure ease of use and fast commissioning. Now in the majority of applications it has become possible to eliminate the need for external controllers.

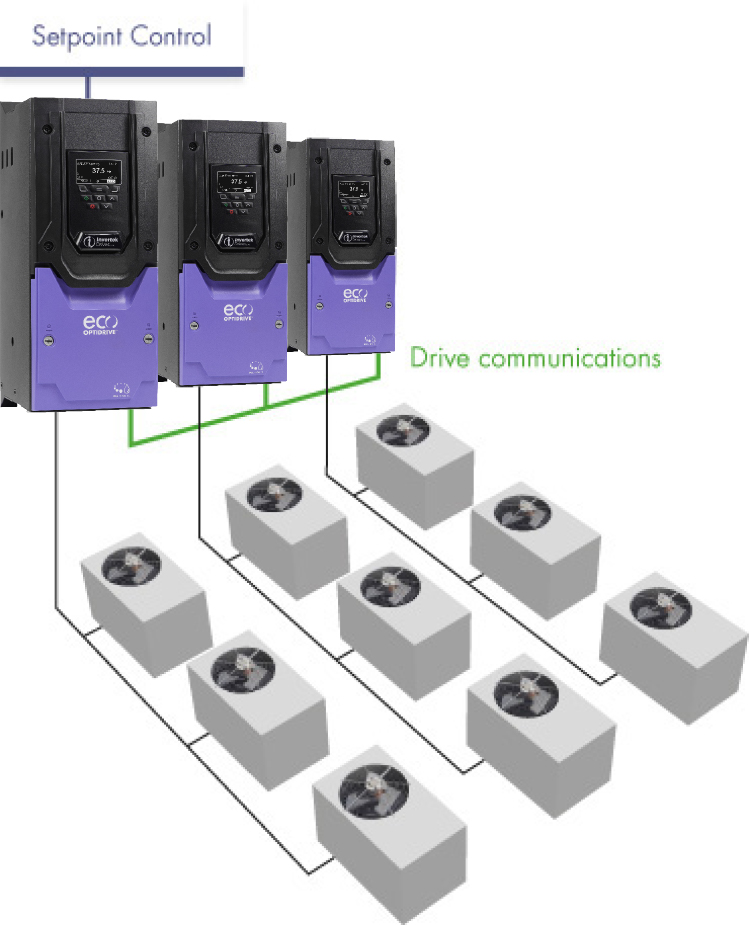

Multiple Fan Operation

Co-ordinated fan station control built-in to each Optidrive Eco as standard allows independent control in multiple fan or fan bank applications.

- All drives operate as variable speed for maximum energy saving.

- Equal run time sharing across each fan / fan bank.

- Automatic system reconfiguration in the event of a fan fault.

- Continued system operation when drives are individually powered off.

- Communication and +24V control voltage shared between drives via a standard RJ45 patch lead.

- Independent maintenance indicators for each fan bank.

- Any fan bank can be switched to Hand operation at the touch of a button and will automatically rejoin the network when switched back to Auto.

- For belt driven fan applications each fan can be set for belt break detection.

- Optional mains isolator with lockoff for safe system maintenance.

- Drives configured through simple parameter set-up and intelligent drive self configuration.

Also ideal for multi-stage/booster set pumping operations.

Optimising Efficiency

Energy Optimisation

The advanced optimisation function intelligently matches energy usage to the fan or pump load to ensure your system operates at maximum efficiency.

Energy Monitoring

The inbuilt energy consumption meters allow energy consumption to be clearly displayed and savings to be calculated.

Resonance Avoidance

Optidrive Eco can be easily configured to avoid frequencies that cause resonance in air handling and pumping systems, preventing unnecessary noise and mechanical damage to motors, ductwork, pipework etc.

In-built Sleep Mode with Auto-boost

Sleep mode saves energy by detecting when the system is running inefficiently and producing little useful work. Optidrive Eco can be programmed to enter into a sleep/disabled mode until the demand increases. To help prevent sleep mode oscillation, Optidrive Eco can automatically initiate a boost cycle to increase pressure on starting or stopping.

Noise Reduction

Quiet Motor Operation

High switching frequency selection (up to 32kHz) ensures motor noise is minimised.

Quiet System Mechanics

Simple skip frequency selection avoids stresses and noise caused by mechanical resonance in ducting or pipework.

Quiet Drive Operation

Temperature-controlled cooling fans ensure quiet operation in periods of reduced load.

Noise Reduction through Speed Control

Optimising motor speed gives significant energy savings and reduces motor noise.

Resonance Avoidance

Resonance frequencies in motors and mechanical components can rapidly cause damage and increased maintenance costs. By programming Optidrive Eco to avoid these frequencies damage can be prevented and maintenance costs reduced. When programmed to skip through a resonance frequency the Optidrive Eco run at the resonant frequency only momentarily (whilst accelerating or decelerating to a safe operating speed), rather than allowing continuously operation at the problematic frequency.

Belt Break Detection

Optidrive Eco can provide immediate warning of broken belt between motor and fan. Due to its simple and flexible configuration the feature can also be used for any loss of load condition, such as broken coupling or other mechanical failure. Optidrive Eco monitors the load output profile throughout the speed range and compares it to normal operating conditions (established during commissioning). Sensitivity adjustment means that it is possible to detect the indications of a belt failure (such as belt slipping) prior to complete failure of the belt.

Drive Controlled Bypass

Optidrive Eco can operate as a bypass controller when installed as part of a bypass circuit. Activation of Bypass mode can be determined intelligently by the Optidrive Eco drive based on a command from the building management system. Additionally the drive can be set to automatically select bypass mode when entering into a trip condition ensuring minimal disruption to service.

Hand/Auto

Allows manual control to easily be selected in the event of an automatic control system failure or for simplified commissioning / system checks, or when a fast temporary override of the control system is required. Built-in ‘Auto Control Selection’ allows return to automatic system control just as easily.