Cranes Hoists and Elevators

Article 17

Lifting and lowering loads are an important application of variable frequency drives, so it’s worth taking a closer look these major users of inverters.

When you lift something, clearly you are doing work; when you lower something, if you’re not using a brake (or too much friction) then you’re taking energy out of the load, so there is regeneration. This means in most applications we need to decide what to do with the energy coming back from the motor. The article “Braking and Regeneration” explains this. In practice, this will mean selecting a suitable braking resistor based on the size of the variable frequency drive, the duty cycle etc. As most elevators have a counterweight, they do not necessarily motor and generate when you expect them to; lifting an empty car will probably result in regeneration.

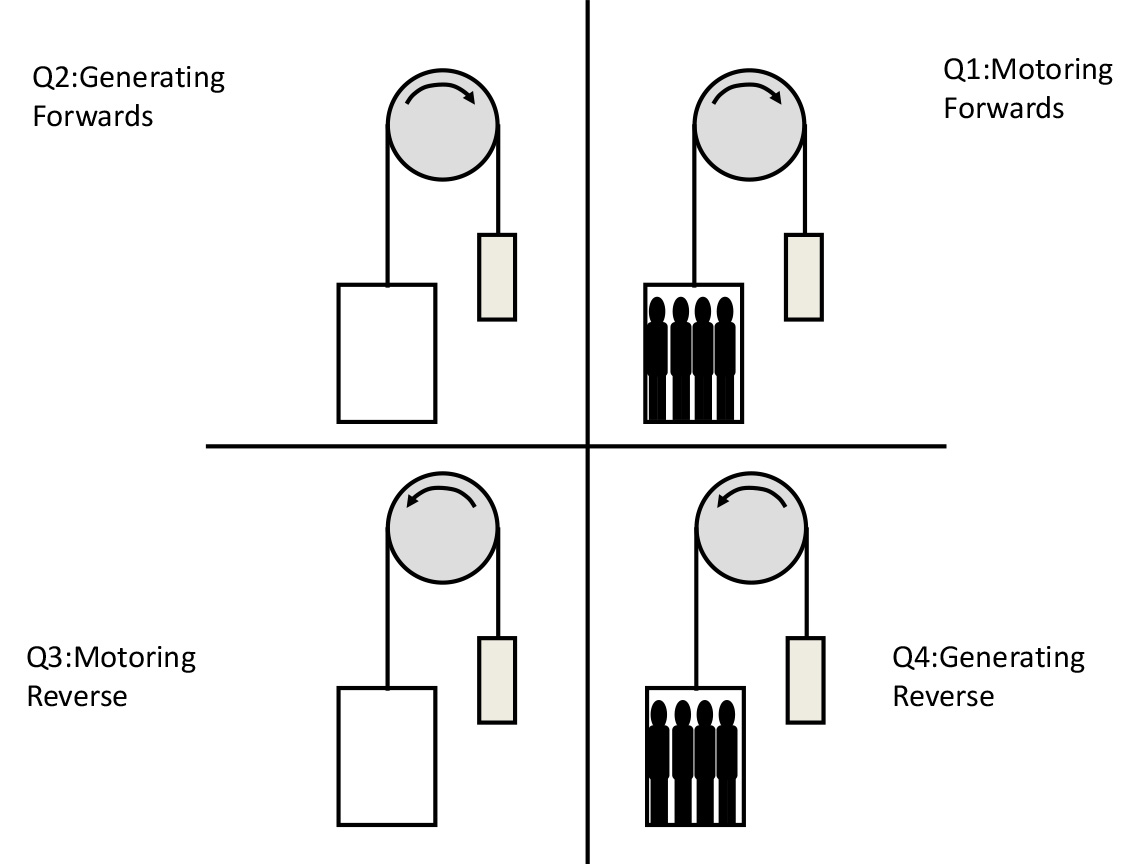

Elevators go up and down, full and empty. This means the drive has to run forward and reverse, motoring or regenerating. This is known as four quadrant operation. Cranes, however, will be pretty close to regenerating lowering a hook or load, and motoring when lifting and therefore only operate in two quadrants. Four Quadrant operation of an Elevator is shown in Figure 1.

The regenerative braking will control the speed of the elevator or crane, but to stop the motion entirely a separate electromechanical brake is needed. These are often controlled by the variable frequency drive via one of its output relays. Usually the brake release is delayed to allow the magnetising current and the torque to build up in the motor; this ensures that when the brake is released the load doesn’t drop while the motor increases torque. Similarly, the brake will be applied just before the motor stops. Parameters allow the adjustment of these times. On some drives such as Invertek’s P2, the motor torque is measured and must reach a certain, preset adjustable level before the brake is released. This is known as torque proving.

Remember if the relay is used to control an electromagnetic brake, a separate contactor (controlled by the relay) must be used as the brake is highly inductive and will easily damage the relay.

As is clear from the above, controlling the motor when the brake is released can be tricky. Until the motor senses the load and begins to turn, it’s not clear if the load is regenerating or motoring. The elevator could be full (tending to drop) or empty (tending to rise due to the counterweight). If the elevator drops even a little before going up, this is not really acceptable to the passengers in the car. An encoder is often used to reduce this effect.

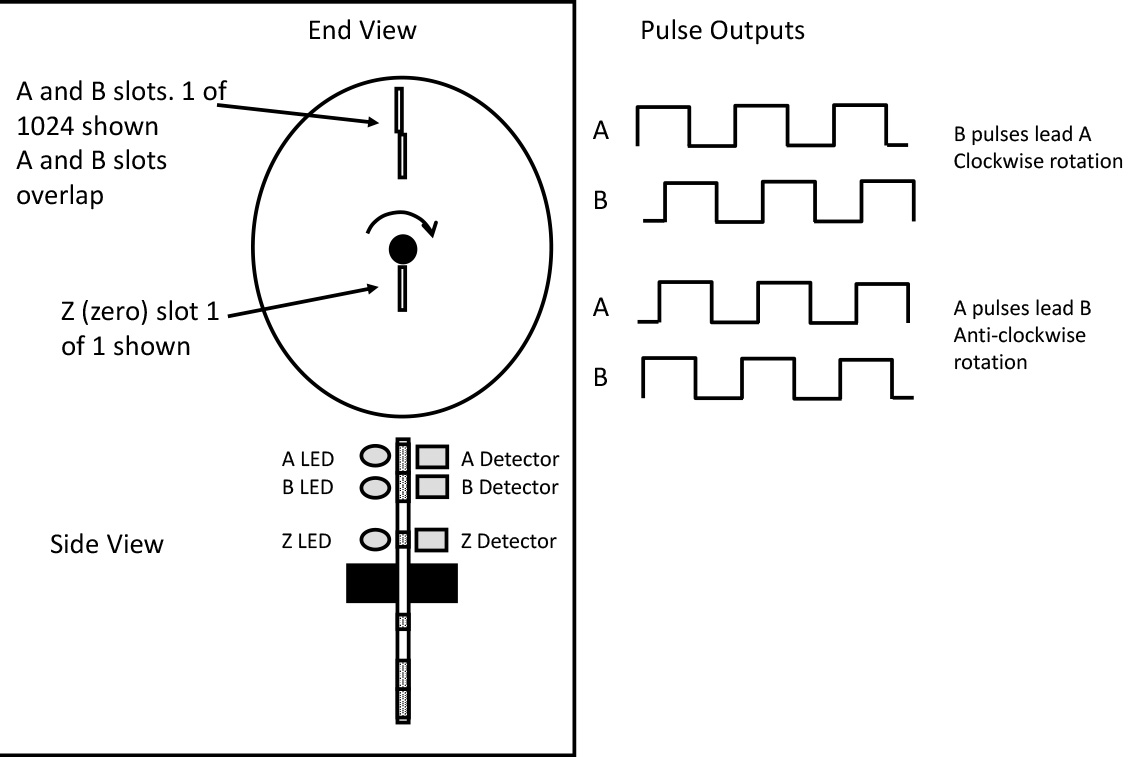

An encoder is a small sensor mounted on the back of the motor and connected to the rotating shaft. As the shaft turns, a disc, mounted within in the encoder rotates, and slots in the disc interrupt the light from an LED on one side of the disc, shining onto a photosensor on the other side. So a series of pulses are generated, whose frequency is proportional to the motor speed. If two sets of slots and photosensors are provided, the direction of rotation can be determined if the slots are offset. The number of slots varies; 1024 per revolution is typical. Figure 2 shows how the encoder works.

If the encoder output is connected to the drive –and the drive has suitable inputs to read and interpret the encoder signal, then the drive can detect the slightest movement as the brake is released and can respond accordingly. Further monitoring of the signal can be used to give precise speed control.

Until recently, encoders have been pretty much standard fitment on elevators and cranes for this reason. However recent improvements in Vector control have made it possible to achieve performance levels similar to encoder control systems using Vector control alone.

Once the stopping and starting has been sorted out, lifting and lowering is pretty straightforward. There may be some safety issues, and larger cranes may have features such as anti-swing software, as well as traverse and travel systems. These together make for a complex machine and may also use high power fully regenerative drives.

Elevators are a bit harder. You need to produce a smooth, safe ride and stop within a few millimetres of the floor. There are safety issues and emergency operation to be considered as well.

These functions can be achieved with a standard drive, but many manufacturers, including Invertek, make a special drive for elevators with software and hardware meeting these requirements.

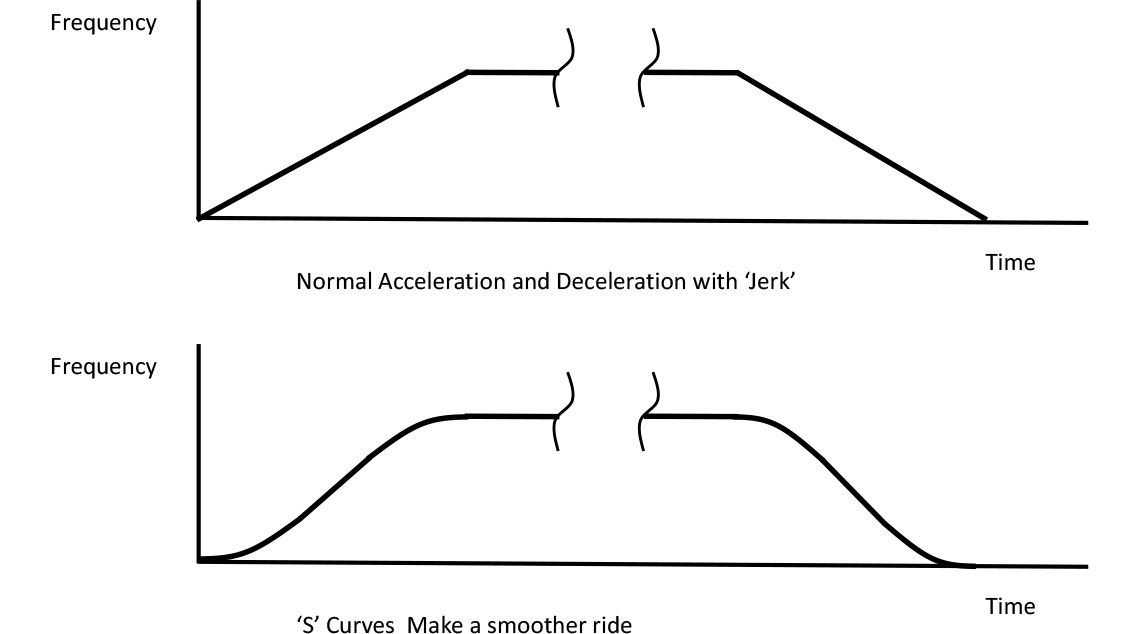

For example, to avoid jerking the car during acceleration and deceleration, ‘S’ curves are used to ensure a smooth stop and start. An optional encoder interface module can be fitted should an encoder be required. Modern elevators use large multipole gearless permanent magnet motors, so the drive is designed to work with these. Figure 3 shows these ‘S’ curves.

Other features may include control of an output contactor and rollback compensation to improve floor alignment when using an encoder.

An important requirement of any elevator system is emergency operation. If the power fails, the elevator should be able to move to the next floor to enable evacuation. This can be achieved using, say, a 24V battery, and running the drive slowly from this; the drive needs significant hardware changes to do this. Another solution is to fit a low cost Uninterruptible Power Supply (UPS), which can supply 230V for a short time to the drive. With minor design changes, a 400V drive can be made to run from the UPS under emergency operation. Either way, the car can travel slowly to the next floor and the passengers can exit to the dark hallway.

The software that controls the lift traffic is highly complex. Consider a six lift system with calls from many floors, up and down, with priority requests etc. Fortunately designing this is the task of the elevator supplier, not the drives engineer.