How to Break a Variable frequency Drive

Article 16

In previous articles we’ve taken the approach that we want to make the best use of our drive; but suppose we want to break it?

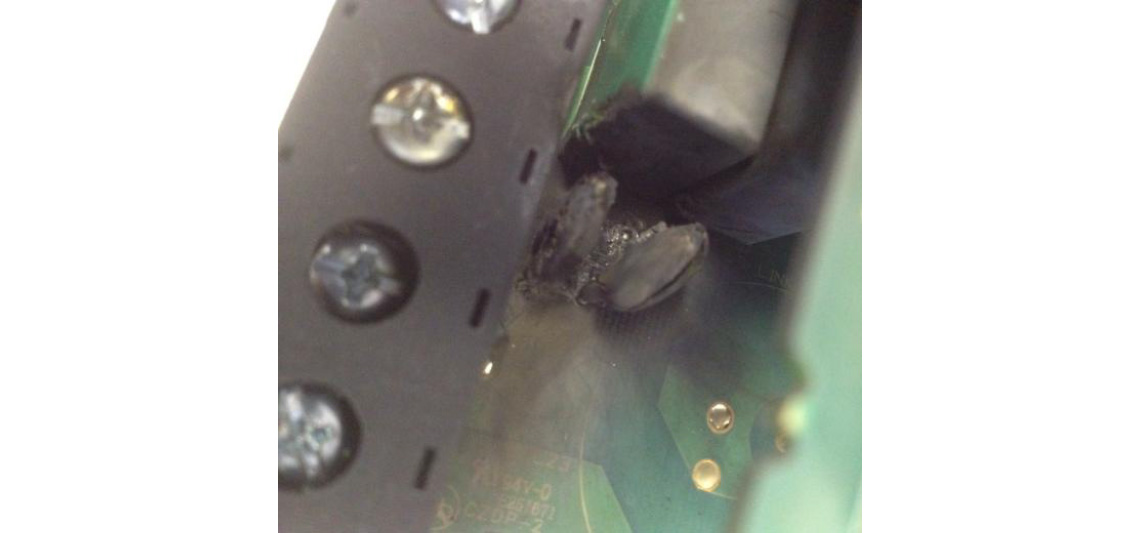

Maybe the easiest way to do this is to connect the drive to an incorrect, higher voltage than specified. Most commonly, this happens when a 230V drive is connected to a 400V supply. Despite labels on the terminals, this still happens. The Varistors on the input to the drive are there to protect from overvoltage, but if there is too much energy, these will fail, as described in a previous article. They’ll burn the printed circuit board and anything else nearby; the drive will probably be damaged beyond repair. Figure 1 shows the result.

So if you don’t want to break it, check the supply voltage you are using and compare it with the information on the rating label.

While you’ve a screwdriver in your hand, try connecting the supply to the output (motor) terminals. You may get away with this, as the commutation diodes will allow the DC capacitor to charge, and the lights come on as usual. But enable the drive and it will self destruct. Again, standard labelling should prevent this, but it still adds to the failure statistics. So if in doubt, check and check again.

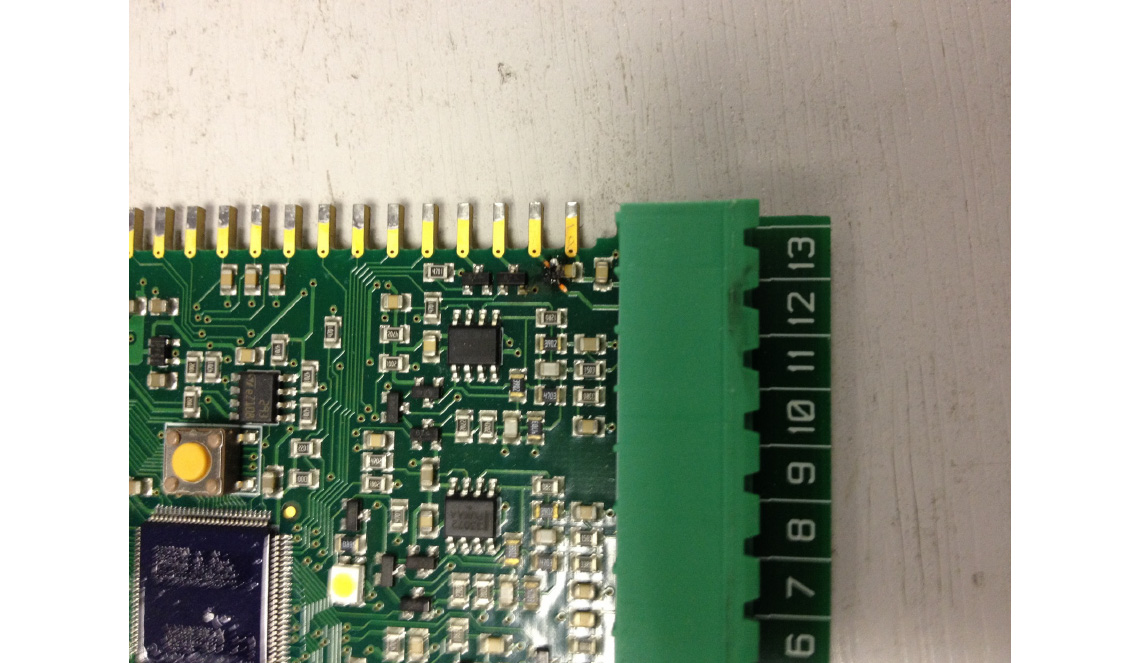

Of course, connecting the mains directly to the control board terminals (or to the serial communications connector) will see off many of the components on the control board; again, there is some protection, but not for supply voltages. Figure 2 shows the burnt pcb track near terminal 13.

The relay connections are actually rated for 230V on Invertek drives, but if you do connect mains there, check and check again.

While you are connecting the drive up, you could get your biggest wireman to tighten the screws way above the recommended torque and wreck the terminal. The torque settings are in the manual, so it’s easy to check.

If the drive is actually wired up correctly, it can be quite difficult to break it in normal running conditions. Drives will protect themselves during overloads or motor faults. If a short circuit occurs on the output (either between two motor connections, or from one connection to ground) the drive will also trip and protect itself. If the drive gets too hot for any reason, temperature sensors within the drive will detect this and raise a warning, tripping if the warning is ignored. However, bear in mind that running at high temperatures for a long time is bad for any electronics, and electrolytic capacitors can dry out, causing them to eventually fail.

In the past, we could often rely on spikes, electrical noise and interference to damage the drive. Voltage transients from power surges, lightning strikes or even other drives could wreck the input rectifiers. Poor installation and bad grounding can also lead to problems on control inputs and serial interfaces. However, drives are much more robust now and damage – except when the spikes have very high energy – is unusual. Maybe if you run an old DC drive next to your new variable frequency drive it might generate commutation spikes that will damage the AC drive. If you expect supply problems or transients and you don’t want to break your drive, fitting an input inductor will give an added level of protection.

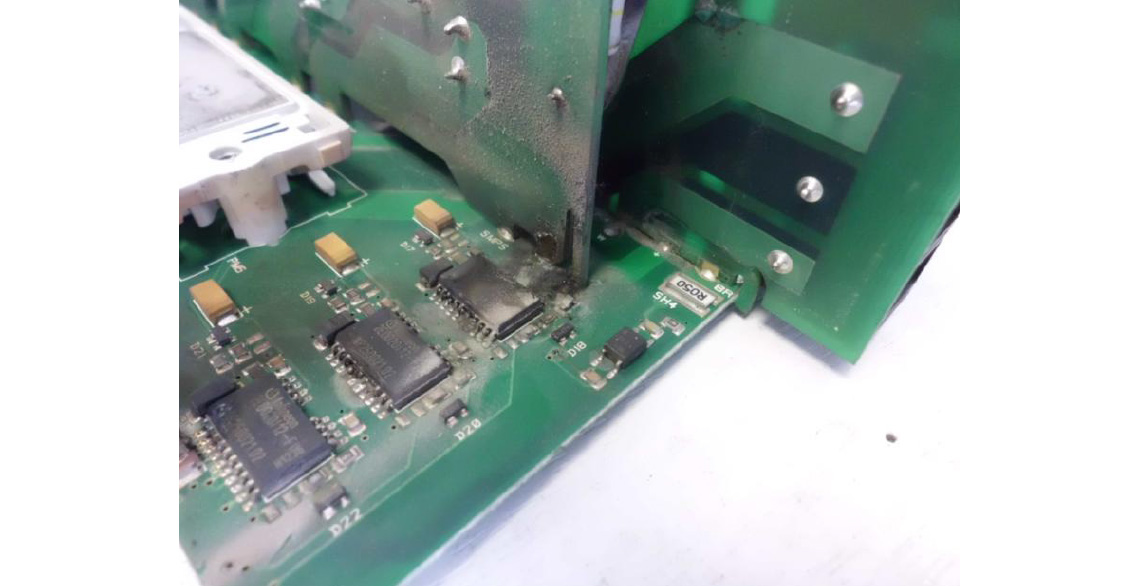

A good way to break the RS485 (serial communication) interface is to drag the connection across the factory and connect it to badly grounded equipment. This could well generate voltages that will damage the interface electronics. Good grounding or isolation circuits will prevent this. Figure 3 shows the effect on the RS485 driver chip.

Perhaps the most common way of breaking a drive is with dirt, dust or liquid. Take an IP20 drive and mount it below pipes that drip condensation, or operate it in a steamy, damp environment. If you have nasty chemicals in the atmosphere these can corrode the insides of the drive, leading inevitably to failure.

Easier maybe is just to ensure there is dust and dirt in the cooling air. This will get drawn into the drive (either by convection or by the action of the drive’s cooling fan) and will build up around areas of high voltage. Now the drive manufacturer has tried to reduce the effect of dust, by increasing creepage and clearance around areas of voltage stress, but with enough contamination, breakdown (or partial breakdown) will occur, leading to an unplanned process shutdown and a call to a drive supplier. If the contamination is conductive, failure will happen pretty quickly. Carbon fibre, smuts from nearby fires and, of course, metal dust are favourites here. But non-conductive dust is almost as bad; flour, wood dust and powders of all sorts will settle inside and provide an easy path for voltage breakdown. If you don’t want this to happen, make sure the cooling air in your cabinets is clean and dry and that there’s no chance of condensation. Of course, if you are using an IP55 or IP66 drive, you have added protection from contamination, and failure is much less likely. Figures 4,5 and 6 show some of the many examples of contamination causing failure.

There are some more unusual ways to convert your variable frequency drive into landfill. You could use it as a step to reach the top of the cubicle. You could try a drop test, or simply shake it apart with high levels of vibration. Again, the manufacturer has done his best to prevent this by meeting certain standards of shock and vibration, but it is always possible to exceed this.

In some drives, components connected to ground may fail if the supply is ungrounded (IT type connection) and you haven’t followed instructions to disconnect them.

If you store the drive for over a year, starting and running the drive without reforming the capacitors may cause problems; any manufacturer will tell you how to reform drives up to 3 years old.

If you succeed in breaking your variable frequency drive and then send it back for service, you may be in for a nasty shock. Many of the above failure modes are easily spotted by service guys who’ve seen it all before, and it’s possible that your warranty claim will be refused.

So if you don’t want to break it after all, just bear in mind the following:

- Connect up correctly; if in doubt, check in the manual or the help card.

- Follow basic rules of installation to prevent Electromagnetic Interference (EMI) problems.

- Adjust the parameters to suit the motor and the application; this will protect the motor as well.

- Make sure the drive is kept cool and free from dust, dirt and liquids.

- Check the drive occasionally to make sure it’s clean, and the terminals are tight.